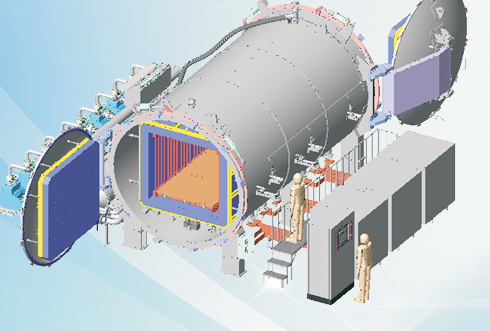

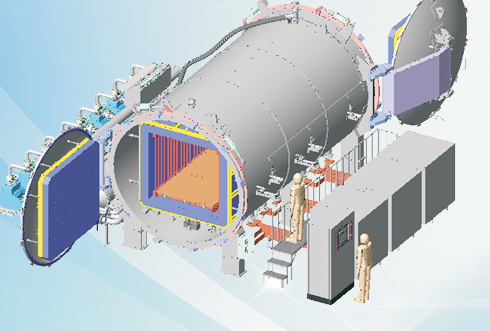

➤ ZSD10-CL:

ZSD10-CL series sintering furnace with a maximum heating temperature of 2500 ℃ , mainly used for hightemperature sintering of recrystallized silicon carbide (RSiC) ceramic products, the preparation of saggers, rollers, and other products are widely used in roller

kilns, in which the recrystallized silicon carbide sagger is particularly suitable for lithium cobaltate , lithium manganese, lithium iron phosphate and other lithium battery cathode material sintering process, the life of the magazine is far more than the traditional mullite and cordierite materials. ZSD10-CL series sintering furnace is equipped with external circulation air cooling system, the whole process of automated control, with a high degree of automation, short cooling time, low energy consumption and other characteristics.